INSPECTO AUTOMATION AG

Quality defects can occur in preforms, even when great care is taken during the manufacturing process.

These flaws, which appear suddenly and unexpectedly, do not only raise costs but annoy customers too.

Is a poor preform batch the result of using cheap raw materials? Is the preform manufacturer to blame for not

taking enough care? Are preforms from low-wage countries of poor quality? - There is no straightforward answer.

Unfortunately, it is often unclear what causes quality defects and sometimes the problem goes unnoticed until

the damage has already been done. Quality control via random sampling always leaves gaps. Continual inspection is the

only way to detect problems immediately.

The best place for quality control

A quality control after the blowing machine (blow-moulder) allows to scan the whole production process but

lowers productivity. In fact, the optimal solution would be in-line quality control during the preform manufacture.

However, there is a drawback : After the preform injection phase, the still-warm and soft preforms would have to

pass through a preform-sorting (unscrambler) unit, which can cause additional damage.

The best solution is to insert the inspection inline before the blowing machine.

But the most profitable solution is the Offline-inspection for production lots with defect.

Profitability of Preform Inspection (Return of investment):

Quality cannot be measured directly in monetary terms, but the damage done by poor quality can cost a lot of trust.

- A whole day's production of faulty bottles, mainly if thy are filled, represents high loss.

- The rejection of a truck load of preform, by the customer for example, will cause high costs.

- As faulty material cannot be processed into new preform, early sorting pays off.

- In in-line bottle filling, a day's lost production will cost more than an inspector!

See

Recycling Inspection Concept

| Production Step: |

Raw material and preform manufacture |

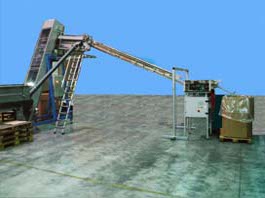

Preform conveyance and feeding into the blow-moulding machine |

Bottle manufacture Blow-moulding machine |

|

|

|

|

| Inspection |

Off-line preform Inspection |

In-line preform Inspection |

In-line bottle inspection |

| Flaw |

Flaws such as black specks

Raw material problems

Transparency problems |

Transport damage

Subsequent material

deformation (oval finish) |

Unequal Wall thickness distribution

Injection point out of centre

Holes on the (feet's)

Finish damaged |

| Inspection |

a. Side-wall Inspection

b. Mouth inspection (finish)

c. Colour measurement

d.Tension analysis (stresslines) |

a. Side-wall inspection

b. Mouth inspection (Finish) |

a. Side-wall inspection

b. Mouth inspection

c. Base inspection

d. Leakage

e. Wall-thickness measurement. |

| Type |

Offline Inspection (a, b, c) |

Inline Inspection (a, b, c) |

|

|

|

Inline Finish Inspection (b)

|

|

|